Extending the Lifetime of Carbon Foils — What Really Matters

- Ahmad Faraz

- Nov 4, 2025

- 1 min read

One of the most significant challenges in accelerator operations is maximizing the lifetime of carbon foils. Because foils operate under extreme physical and thermal conditions, even the smallest irregularities in vacuum, beam alignment, or foil thickness can drastically affect their performance and longevity.

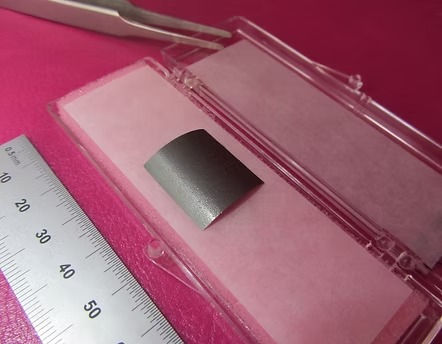

At ACF Metals, we have dedicated decades of research to understanding and controlling these variables. Our foils are produced using high-purity materials and meticulously refined manufacturing methods that minimize internal stress and surface imperfections. The result is a foil that maintains structural integrity and charge efficiency even after prolonged exposure to high-energy ion beams.

Mounting design is another key factor in foil longevity. ACF Metals offers pre-mounted foils on cyclotron forks precisely fitted for each client’s system, reducing manual handling and alignment errors. This not only extends foil life but also minimizes downtime, allowing continuous and uninterrupted research or isotope production cycles.

Ultimately, a longer-lasting foil means greater efficiency and reduced operational costs.

With ACF Metals’ advanced carbon foil technology, laboratories can achieve consistent, reliable, and cost-effective performance, ensuring smoother workflow and improved results across every experiment or production batch.

Comments